Dynovas Develops Type IV COPV for Gaseous Hydrogen Storage

San Diego, CA, December 2024 – Dynovas, Inc. has successfully manufactured an Engineering Development Unit (EDU) for the High Efficiency Lined Pressurized – Gas Storage (HELP-GAS) system. The Dynovas team is supporting the Navy’s call for lightweight hydrogen storage COPVs to better enable fuel cell applications in UAS Naval Aviation vehicles. Dynovas is responsible for the design, structural analysis, manufacturing development, and testing of the Type IV COPV.

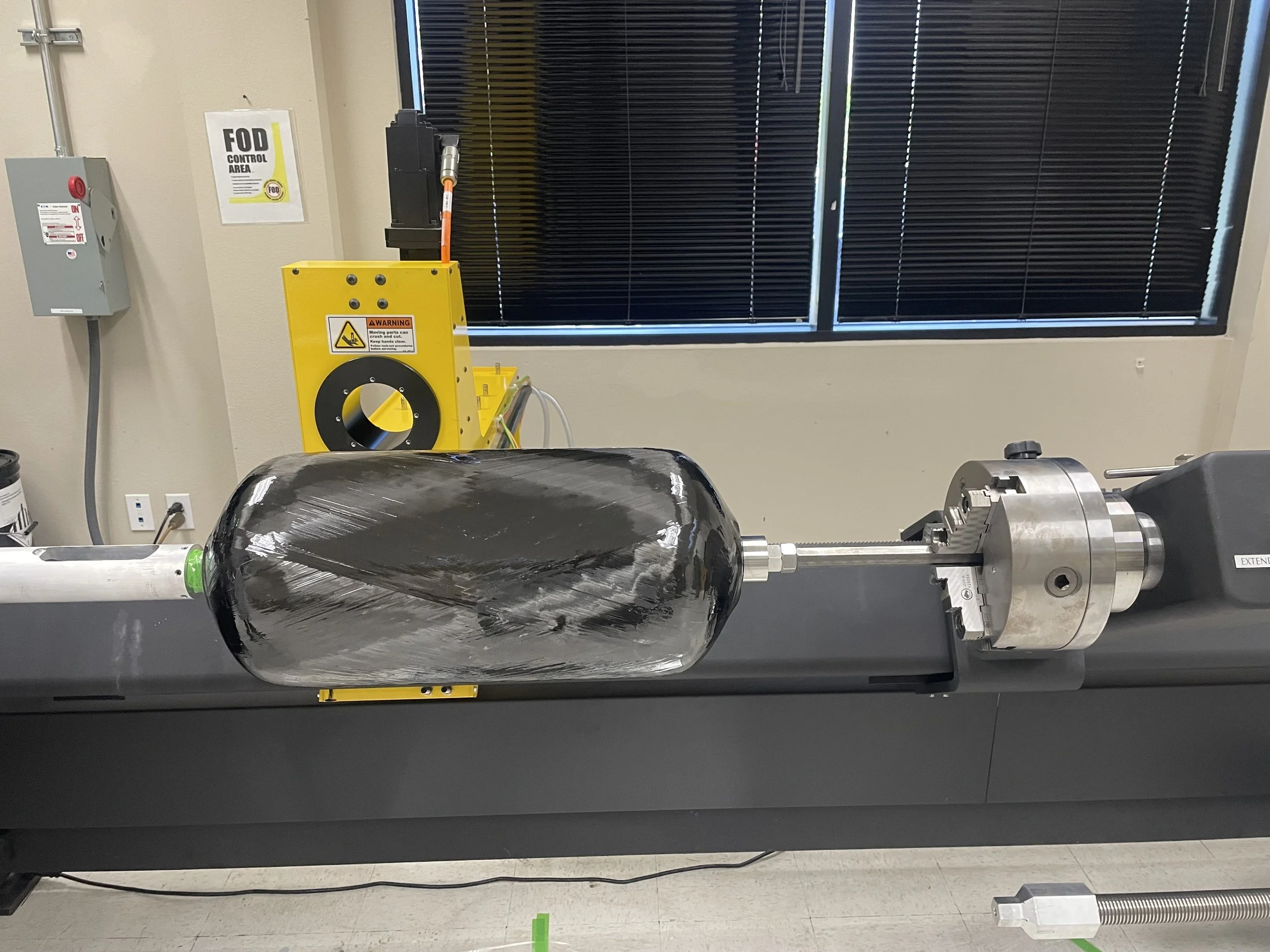

HELP-GAS COPV - Filament Winding

Dynovas, Inc Manufacturing Facilities

Dynovas’ HELP-GAS COPV technology is focused on improving performance over metallic-lined Type III pressure vessels. Through integration of key technologies and well-established industry techniques into subscale articles, Dynovas advanced the TRL and MRL of HELP-GAS while working alongside key OEM partners to align system objectives and requirements.

The development of the HELP-GAS Type IV COPV incorporates CNC-machined metallic port bosses that are integrated to the thin-wall polymer liner and serve as the pressure inlet/outlet and vehicle interface.

HELP-GAS Polymer Liner

With in-house filament winding capabilities and finite element analysis tools, Dynovas is now positioned to further develop and iterate on the HELP-GAS overwrap design. Our established material database allows the Dynovas team to provide our customer options when using industry leading high strength fibers combined with most thermoset and thermoplastic resin systems. Both towpreg and wet filament winding options are available applications supported by Dynovas’ facilities.

HELP-GAS Liner - Filament Widing Process

HELP-GAS COPV - Curing Process

Next steps for Dynovas and HELP-GAS System development is to perform proto-flight level qualification testing including: proof pressure, cyclic thermal pressure testing, drop-impact testing, Non-destructive Inspection, and acceptance pressure testing.